LIQUID BOOT EMEA Landing Page

CETCO’s LIQUID BOOT® Vapor Barrier solution safeguards indoor air quality from vapor intrusion from volatile soil and groundwater contaminants. With over 50 million square feet of successful global installations, LIQUID BOOT® Vapor Barrier is utilized in hospitals, schools, libraries, commercial buildings, multi-family housing developments, and major public works projects. LIQUID BOOT® Vapor Barrier is the premier vapor intrusion barrier system.

CETCO’s LIQUID BOOT® Vapor Barrier solution safeguards indoor air quality from vapor intrusion from volatile soil and groundwater contaminants. With over 50 million square feet of successful global installations, LIQUID BOOT® Vapor Barrier is utilized in hospitals, schools, libraries, commercial buildings, multi-family housing developments, and major public works projects. LIQUID BOOT® Vapor Barrier is the premier vapor intrusion barrier system.

LIQUID BOOT Vapor Barrier forms a barrier at a structure’s foundation that prevents vapor intrusion by subsurface chemicals in the ground below, including:

LIQUID BOOT reduces vapor intrusion from these chemicals to protect against the potentially serious health risks they pose.

LIQUID BOOT seals surfaces and penetrations, creating a seamless, monolithic membrane that fully adheres without mechanical fastening and protects against both vapor and non-hydrostatic nuisance water migration.

LIQUID BOOT is available in various formulations to best mitigate specific vapor intrusion situations:

LIQUID BOOT - For moderate-risk underslab and below-grade vertical walls, LIQUID BOOT® is an effective vapor intrusion barrier for methane, CO2, and low-level VOCs such as BTEX and chlorinated solvents. It can also be used as a concrete water reservoir and tank liner to prevent water seepage into concrete.

LIQUID BOOT PLUS – For high-risk underslab and below-grade vertical walls, LIQUID BOOT® PLUS combines traditional Liquid Boot® spray-applied membrane with high-performance VI‑20™, a 20-mil polyethylene-EVOH copolymer membrane, to form a superior vapor intrusion barrier that’s ideal for VOCs including BTEX and chlorinated solvents.

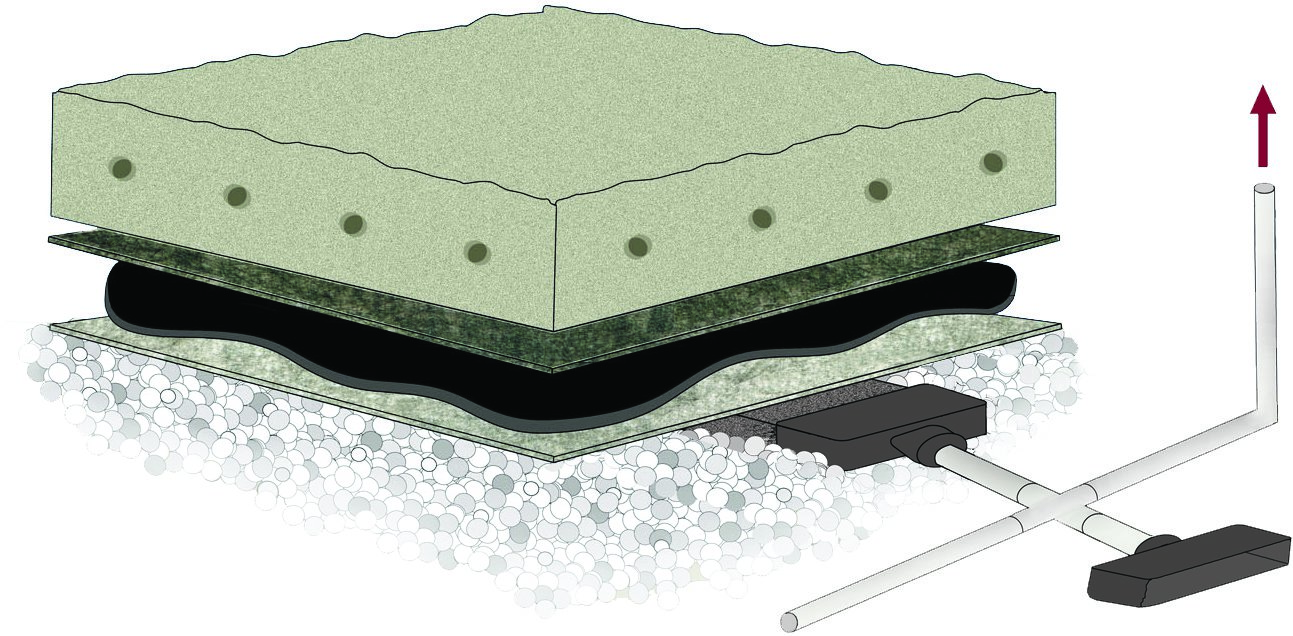

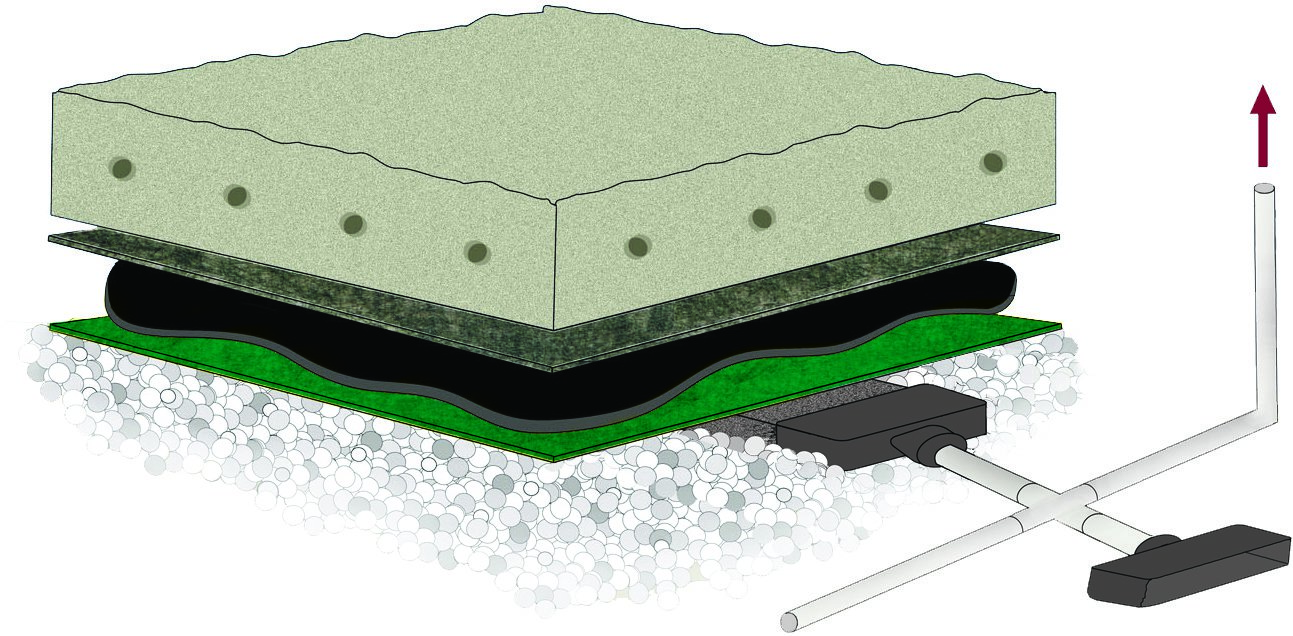

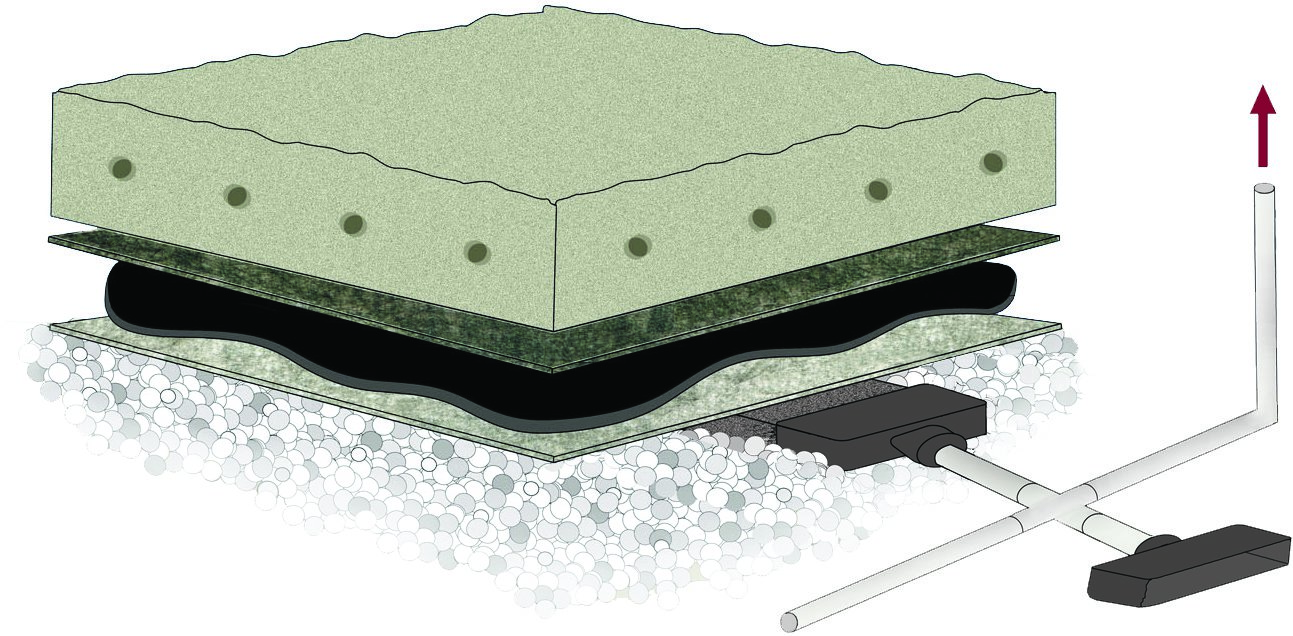

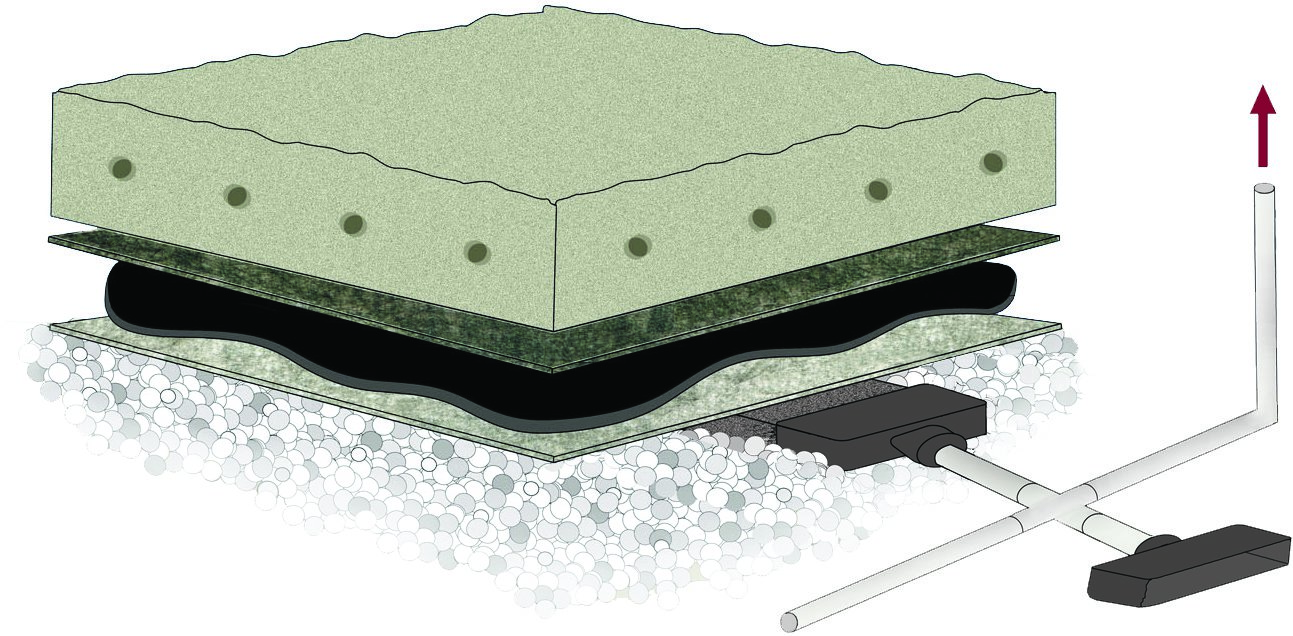

Even greater contaminant resistance is achieved when LIQUID BOOT PLUS is installed with our GEOVENT gas venting system along with a course of our ULTRASHIELD non-woven geotextile protection to create a superior, highly-resistant protection barrier.

LIQUID BOOT LT - Designed for colder climates to allow for lower spraying temperature.

LIQUID BOOT 500 - For low-risk underslab applications, LIQUID BOOT 500 is an effective vapor intrusion barrier for methane and CO 2. It has a reduced elasticity for a more economical choice.

| LIQUID BOOT | LIQUID BOOT Plus | LIQUID BOOT LT | LIQUID BOOT 500 | |

| Membrane (min. dry thickness) | LIQUID BOOT (60 mils) | LIQUID BOOT (60 mils) | LIQUID BOOT (60 mils) | LIQUID BOOT 500 (60 mils) |

| Substrate | Prepared concrete or BASEFABRIC | VI-20 | Prepared concrete or BASEFABRIC | Prepared concrete or BASEFABRIC |

| Protection | ULTRASHIELD G-Series | ULTRASHIELD G-Series | ULTRASHIELD G-Series | ULTRASHIELD G-Series |

| Venting | GEOVENT | GEOVENT | GEOVENT | GEOVENT |

| Drainage | ULTRADRAIN | ULTRADRAIN | ULTRADRAIN | ULTRADRAIN |

| Recommended applications | Methane, CO2, low levels of VOCs (BTEX, chlorinated solvents) | VOCs (BTEX, chlorinated solvents) | Methane, CO2, low levels of VOCs (BTEX, chlorinated solvents) | Methane, CO2 |

| Applications | For moderate risk, horizontal & wall applications | For high risk, horizontal & wall applications | For moderate risk, horizontal & wall applications | For low risk, horizontal applications |

LIQUID BOOT is a seamless, spray-applied rubberized asphalt formed from a waterborne emulsion and catalyst that are sprayed simultaneously from a dual-nozzle wand and combined with a geomembrane to create an effective protective barrier against vapor intrusion into a structure.

LIQUID BOOT PLUS combines the advantages of LIQUID BOOT with VI-20™, a seven-layer co-extruded EVOH geomembrane made using high quality virgin-grade polyethylene and barrier resins for impact strength and VOC vapor transmission resistance. EVOH is a copolymer of polyethylene, polyvinyl alcohol, and ethylene vinyl alcohol that demonstrates OC diffusion coefficients 20 times lower than 80 mil HDPE geomembrane to restrict methane, radon, and other harmful chemicals.