The Gold Standard of Construction Waterproofing

COREFLEX waterproofing membrane sets the standard for waterproofing, with over 50 years of unmatched strength, durability, ease of installation, and performance.

For cast-in-place concrete, masonry block foundation walls, or soldier pile and lagging, the COREFLEX waterproofing system provides waterproofing protection for any structural below-grade concrete surface, such as:

|

|

Whether a structure is under continuous or intermittent hydrostatic pressure, COREFLEX is your most reliable barrier against water. Combining two kinds of barriers—passive and active—COREFLEX substantially reduces the possibility for leaks, with its traditional passive barrier blocking water while the active volcanic bentonite component of its core absorbs up to 15 times its volume in water, expanding to seal cracks using the very pressure of the water itself to fill and block any gaps.

Easy to install even in cold weather, COREFLEX is also easy on your budget, saving you money in time and installation, especially in remedial waterproofing projects. With no additional preparation, simply lay it over any existing surface requiring waterproofing—even an already-treated surface, no primers or adhesives required. Flexible COREFLEX not only conforms easily, but its fibrous outer layer bonds to nearly any concrete surface—it can even be continued under a floor slab and up onto a horizontal deck for continuous, uniform waterproofing.

COREFLEX is extremely durable. Self-sealing and self-seaming—the only composite barrier with this ability—there’s no worries about the inevitable cuts and punctures that always occur on construction sites. What’s more, COREFLEX is fire retardant, with component materials that self-extinguish to prevent the spread of flames when most other water barrier products burn and fall apart. And COREFLEX resists chemicals and harsh contaminants such as diesel, kerosene, or jet fuel, providing protection that qualifies it as a Class “A” vapor retarder and certified methane barrier.

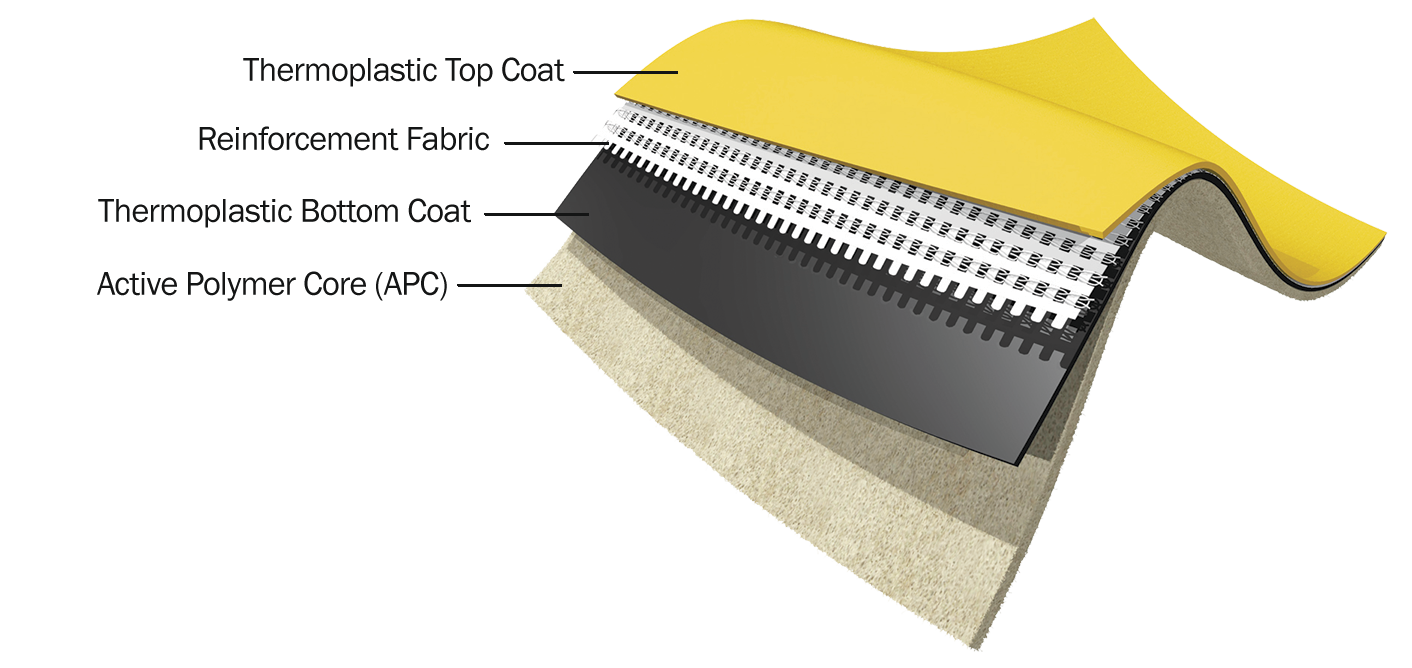

COREFLEX features a 1.5 mm (60 mil) nominal thermoplastic membrane with welded seams that provide a watertight barrier layer. It’s reinforced with a 5.0 oz weft inserted knit polyester fabric integrally bonded to an Active Polymer Core (APC). The fabric is produced with DuPont’s Elvaloy-KEE® (Keytone Ethylene Ester), a solid phase high molecular weight ethylene interpolymer that also provides superior chemical resistance.

Unlike traditional liquid PVC plasticizers, the Elvaloy-KEE doesn’t experience phase separation and migrate out—in other words, the membrane properties are maintained for long-term performance, with the Active Polymer Core layer integrally bonded to the Elvaloy-KEE thermoplastic membrane. Employing the mineral bentonite, the core is designed to activate with water and swell to form a positive seal. The APC layer reacts at the breach of any puncture or defect to self-seal and prevent water ingress—COREFLEX is the only welded thermoplastic membrane composite with this reactive, self-sealing feature.

CETCO is the leader and pioneer in cutting-edge waterproofing membranes. Around the globe, our innovative teams of clay mineralogists, chemists, and polymer scientists transform ordinary minerals into extraordinary technology to solve day-to-day problems worldwide.