Innovative material solutions for challenging applications.

Pyroid® pyrolytic graphite's single crystal structure offers unique performance capability and stability in extreme environments.

Our PG material has a density of 2.23 g/cm3 which is greater than any known graphite. This means that there is no porosity due to ash contamination in the material that would otherwise degrade its structure when exposed to harsh application environments. PG exhibits stability at high and low temperatures, resistance to thermal shock and chemical erosion. These characteristics, along with the anisotropic nature of the material, lead to incredibly low erosion rates, and longer service life.

Pyroid® pyrolytic graphite (PG) is a "five-nine" purity, chemical vapor deposition (CVD), carbon product grown atom-by-atom that offers unique thermal, electrical and chemical properties including a very low erosion rate.

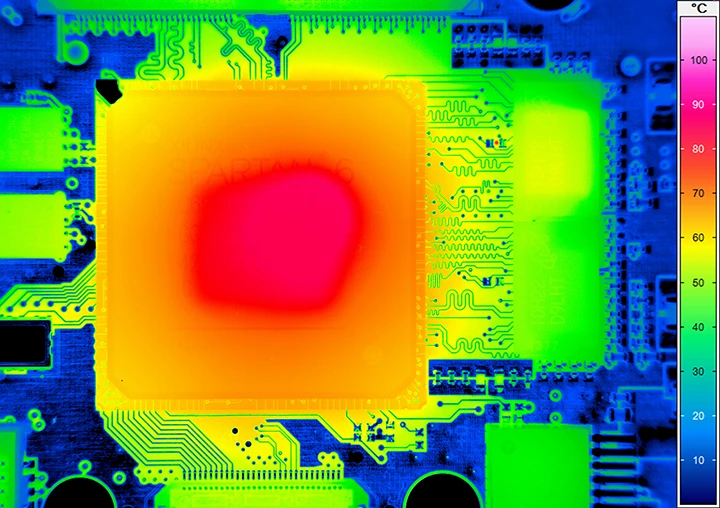

Pyroid® HT is an ideal solution for any application where excessive heat generation exists, offering an in-plane thermal conductivity of 1500 W/m·K, while weighing 75% less than copper.

Pyroid® PG foils are high-purity, free standing foils used to strip electrons in the process of manufacturing radionuclides.

For over 40 years, our FIREX™ coatings have provided fire and thermal protection for personnel and property. FIREX coatings are used in numerous military and defense applications to buy critical time for the containment and suppression of thermal threats to personnel, equipment, and structures.

FIREX formulations combine modified epoxy binders with thermally active materials that form cooling gases when exposed to temperatures in excess of 350°F. When exposed to temperatures between 1000ºF and 5000°F, a char forms which insulates by transpirational cooling and re-radiation.