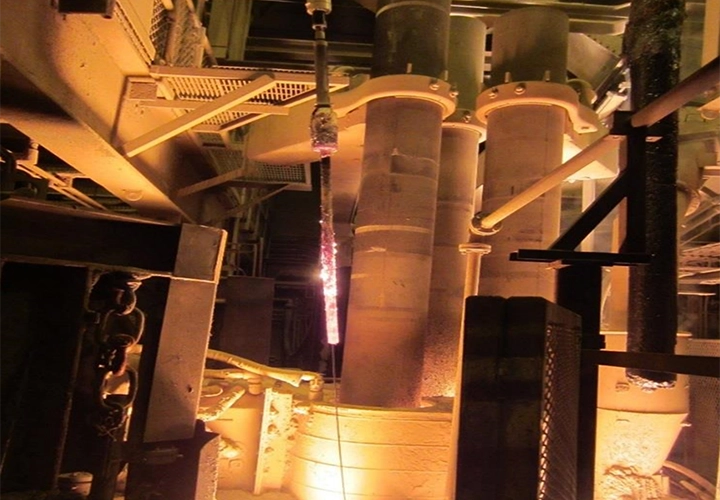

Industry leader for thin slab casting treatment.

Our Sure-Cal® calcium metal injection technology provides the most efficient and reliable method of calcium treatment in steelmaking, enhancing steel quality and productivity in our customers' operations.

Our wide range of industry-standard alloys and ferro-alloys in powder-filled metallurgical wires are offered in a variety of diameters from 9mm to 16mm. We offer a full product line of calcium, calcium silicate, alloy, and aluminum wires. These products are used in various molten steel processes and foundries and are also widely accepted in the production of non-ferrous metals.